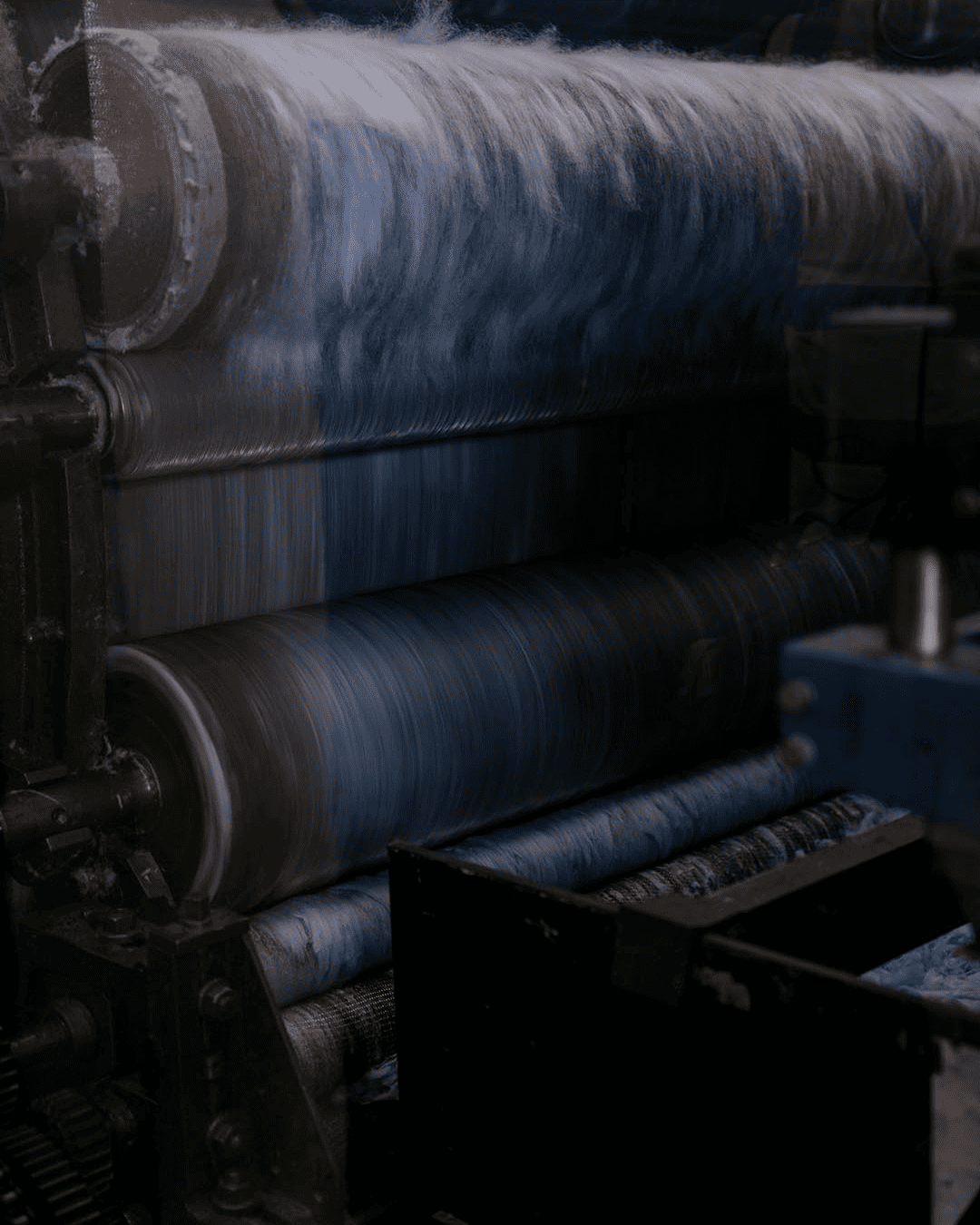

Every dunhill garment is the result of collaboration, a community of makers united by shared values of skill, care, and continuity. In the Scottish Borders, knitwear specialists hand-link and finish each piece with a level of control no machine could replicate. In the North of England and the South West, traditional tailors work cloth pressed on Hoffman steam tables. Spinners and weavers uphold the codes of traditional craftsmanship while embracing modern innovation.

Together, they form an ecosystem of excellence, a living chain of knowledge that connects workshops, towns, and families across Britain. At each mill, multi-stage quality control ensures the integrity of every roll of cloth. At one weaving house, cloth must pass through three separate verification steps before it leaves the floor. It is a standard that speaks of pride. Many of our partners run in-house training schools, linking local colleges to intergenerational knowledge. In this way, dunhill garments become part of a living craft culture - made possible by community.